& nbsp; & nbsp; & nbsp; & nbsp; Dalian metallurgy provides many cylindrical roller bearings of different designs, size series and sizes. Most of them are single row bearings with a cage. In addition, single row and double row full roller bearings (without cage) constitute the standard configuration of bearing varieties used in general engineering by AWD. The bearing with cage can bear large radial load and run at high speed. Full roller bearings are suitable for very heavy radial loads at medium speeds. & nbsp; & nbsp; & nbsp; cylindrical roller bearing, roller is one of the key components. Its geometry, the so-called logarithmic shape, provides the best stress distribution in the contact area of the bearing. Its surface finish can promote the formation of lubricant film and optimize the rolling of roller. Compared with traditional design, the benefits from simultaneous interpreting include increasing operational reliability and greater tolerance for misalignment. dyzv cylindrical roller bearing has the following design features: 1. Optimizing the design of roller and flange can improve the axial bearing capacity of bearing 2. Optimize the geometric surface design between roller and raceway to balance the radial load 3.limit the width of the wheel cross groove, increase the contact area between the raceway and the roller and improve the radial bearing capacity 4. Adopt high standard materials and strictly control the content of elements in materials, such as Ti & lt; 30ppm (titanium content) 5. Low noise design is adopted to achieve V1 noise level, which is conducive to low noise operation of automobile engine and gearbox.

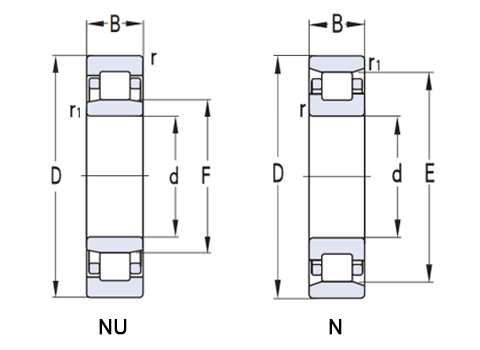

Cylindrical roller bearing

Cylindrical roller bearing